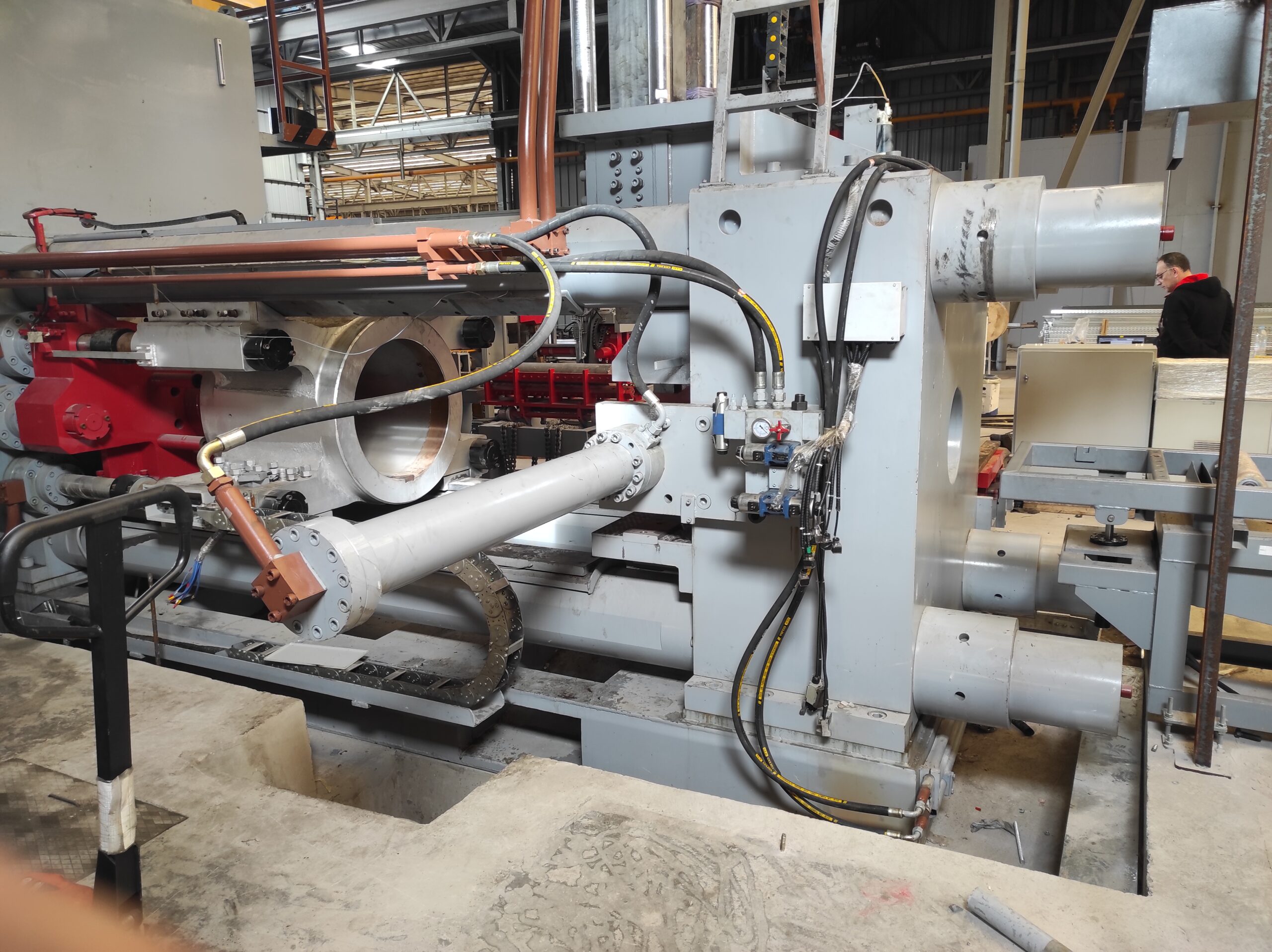

Complete Aluminium Extrusion Solutions

Turnkey extrusion lines built for stable output and long-term performance.

LBB Systems Technologies delivers integrated aluminium extrusion line solutions — from concept and layout to installation, commissioning and after-sales support. Designed to maximize productivity, quality and efficiency.

Experienced Team

Engineering-driven, field-proven mindset for real production conditions.

Integrated Line Design

Press, heating, handling and auxiliary equipment aligned as one system.

24/7 Communication

Fast coordination via WhatsApp-style communication for critical topics.

Passionate – Dedicated – Professional

A line that runs smoothly – not just a line that gets installed.

Our extrusion line approach focuses on the full production flow: billet heating → pressing → quenching → handling → cutting → finishing readiness. We optimize for stability, consistency and operator-friendly workflows.

Passionate – Dedicated – Professional

The Steps We Follow to Achieve Your Goals

A structured project approach that aligns expectations and reduces risk — from early planning to stable production.

Passionate – Dedicated – Professional

Key line modules that impact throughput and quality.

Below are example focus areas within a complete line. Exact scope is customized to your plant, profiles and targets.