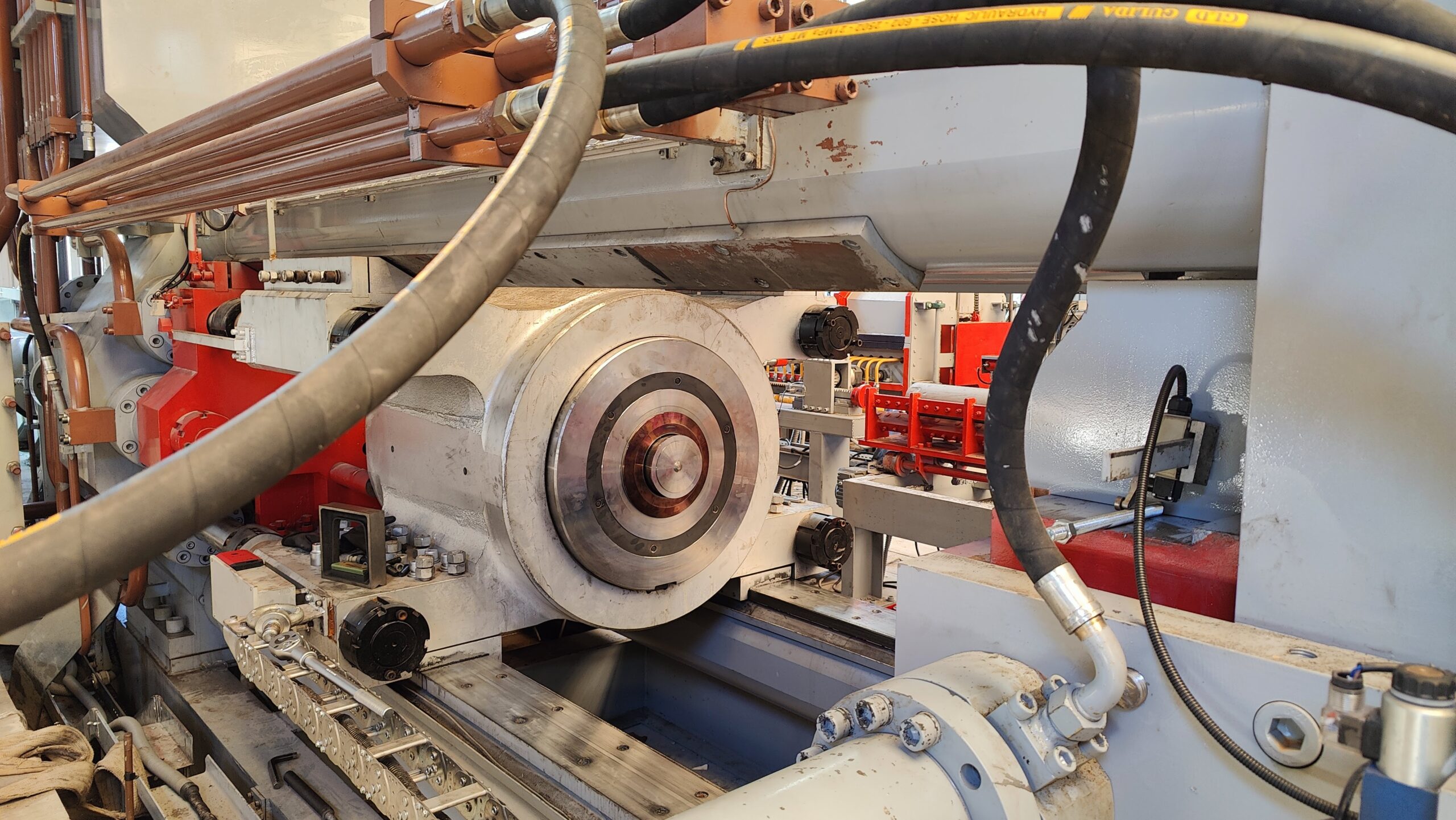

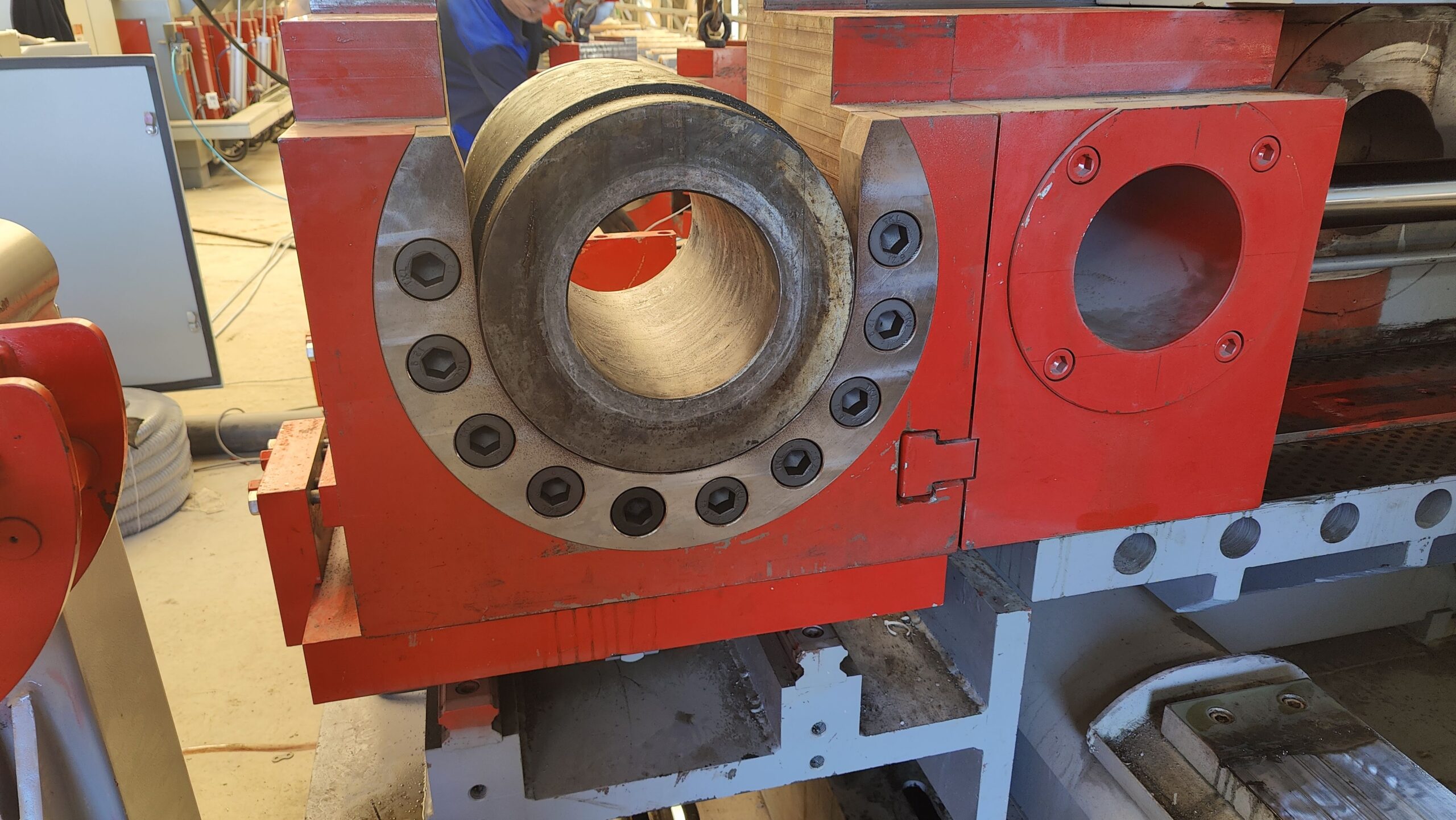

Complete Aluminium Extrusion Solutions

Upgrade your extrusion line for higher output, safer operation and stable quality.

LBB Systems Technologies provides line revamping solutions that modernize key equipment, remove bottlenecks and improve reliability — while minimizing downtime and protecting production continuity.

Minimum Downtime

Phased upgrades and planning to keep production disruptions low.

Measurable Gains

Improvements tied to KPIs: OEE, scrap rate, downtime, throughput.

Lifecycle Support

Engineering, installation, commissioning and after-sales service support.

Passionate – Dedicated – Professional

Revamping that targets the real bottlenecks.

We focus on upgrades that bring practical operational impact. From mechanical improvements to workflow enhancements, we help you achieve stable production with improved safety and maintainability.

Passionate – Dedicated – Professional

The Steps We Follow to Achieve Your Goals

A structured approach that minimizes risk, keeps production planning realistic, and ensures measurable results.

Passionate – Dedicated – Professional

High-impact revamping focus areas.

Typical revamp modules are tailored to your current line condition, targets and budget.